Recently, a customer posed a question about stretching the limits of barcodes.

“How small can a barcode get?”

This customer requires barcodes as small as possible. As this is not a question we receive every day, we decided to do some testing to find out. We already knew that the best option for tagging small items would be a 2D barcode, but we didn’t know all of its limitations. So we proceeded to make some samples and identify the limits of how small we could go!

From a manufacturing perspective, we needed to address two issues:

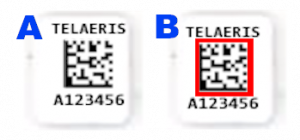

1. The very slight issues with registration between the printing and die cutting. Normally these are on the order of half a mm top to bottom and left to right, but with small barcodes, this can become an issue. In example A below, it is clear that the text and barcode are not centered in the tag – we had to avoid this.

2. Quiet zones need to be maintained for 2D barcodes of one cell equivalent around the edge of the barcode. In example B below, the red zone is the quiet zone, which is required for readability of the barcodes.

I should also mention that we had two constraints imposed on us by our customer. They wanted:

- A six-digit number preceded by a letter – good for up to 27 million unique barcodes.

- A human-readable number that could be read with the naked eye below the company information as the header.

- And the label had to be readable by all of the following barcode readers

So, Just How Small Can We Get?

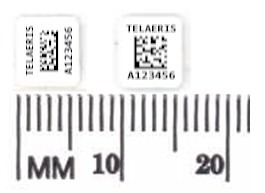

As it turned out, the printing of the company information and human readable were the final limiting issues for the size of the tag. In terms of the barcode size, we were able to get the following sizes for 2D Data Matrix barcodes to be readable for all the associated readers:

| Cell Size | Barcode Dimensions |

| 12 x 12 cell | 3mm X 3mm |

| 8 x 18 cell | 2mm X 4mm |

The final barcode tag size for this customer was 5mm x 5mm. Could we have gone smaller? Most certainly! But given the limitations of their scanners’ reading capability and the need for a human eye readable number, this was the appropriate tag for this customer.

If your company has difficult tagging problems – or just a question that is out of the ordinary, please drop us a e-mail and let us see if we can solve it for you!

This post was originally posted June 20, 2012, and updated January 10, 2019.

We have samples from our showroom that move quite often throughout the year, we would like to be able to tag them, scan them with our I pad or phone and get a list of the movements during the year when the samples move to customer visits and back.

Hi Mike!

Thank you for your comment. There are a number of products that can provide a solution for you- in particular, one of our products, XPressTools might be a solution! We do custom projects, and if you would like, we would be more than happy to talk in detail. Give us a call or shoot us an e-mail.

Hi Thank you for your analysis of bar code sizes. Just for interest sake, do you call all scannable codes bar codes as we call the codes you tested QR codes in Australia.

I find “barcodes” as a good general name for all scannable codes.

QR codes and Datamatrix are two-dimensional (2D) barcodes.

Code 39 and Code 128 are more traditional 1D barcodes.

There are other codes like Ultracode that use color to encode data.

This is pretty standard in the industry, see: Wikipedia – Barcodes

Very nice blog.

Thanks for sharing.