Automation – it’s what modern-day technology is all about!

Recently, Telaeris was asked to simplify employee timekeeping for a construction yard using radio frequency identification (RFID) technology. The company had 3000 employees and wanted to know both who was on the job site and when they came and left. Instead of hand-punched time-cards which were tedious and error-prone, we provided them with an elegant, effective, and most importantly, automated solution. Here’s how it worked:

First, an RFID tag was placed on each employee hard-hat.

Next, we placed two long-range UHF RFID antennas at each gate. As each employee passed through the gate and the antennas, the readers captured the employee direction and tag information.

Finally, all of this data is automatically fed into our XPressEntry system and database. We track exactly every employee entry and exit each day to calculate their daily time. But more importantly, we keep continuous account of who is on-site, so in case of an emergency, the employer knows immediately who is on the job, improving employee safety.

That’s it!

It’s nice to have a system function so straightforwardly, but there are many factors that we had to consider for this project. Below is an in-depth explanation of the RFID technology behind it and what we based our choices on.

The RFID Tag

When deciding on the tag placement and tag type for any situation, it is important to keep a few factors in mind:

Use Case Environment: In this customer’s application, the tag was going to be regularly exposed to the elements – specifically sun and rain. It needed to be rugged enough to endure prolonged exposure.

Required Tag Durability: Since this was for a construction company, we knew these tags were going to be exposed to dirt, dust, and oils every day. Additionally, we expected that with the hard work the employees were doing, the tags could get banged around quite a bit.

Mounting Requirements: Some customers are able to wear UHF cards in lanyards or have tags on wristbands for tracking their people. This customer wanted to have the tag affixed to the employee hard hat without modifying the helmet as this could damage the integrity of the helmet’s safety performance. This required a tag that was flexible enough to conform to the curved helmet and a strong adhesive that would hold it indefinitely.

Tag Location Placement: We considered placing the tag on the inside of the hat to keep it more protected. However, an interesting fact about RFID tags is when they are too close to a human body, they become ineffective. Water, which makes up 60% of our bodies, absorbs RF energy. Placing a tag on the inside of the hat near the back of the head would likely decrease the tag read range. To improve the tag performance, we chose to place the tag on the outside back of the hard hat. While this would leave it more exposed, it would provide more reliable tag readability. This location had the additional benefit of allowing us to better differentiate between entries and exits, by appropriate placement of the antennas.

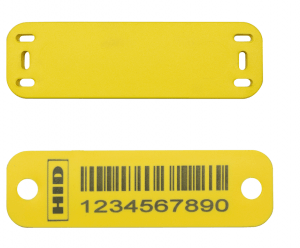

To meet our requirements, we chose a tag from the HID SlimFex line of UHF tags. This tag is flexible and durable, with great read characteristics.

The Antenna

Similar to choosing tags, there are a few considerations to make when deciding on the antenna characteristics, polarization, number and placements of antenna.

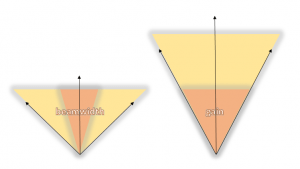

Characteristics: We needed to examine antenna gain and beam width. Gain is the relative strength of the energy an antenna can transmit. The beam width describes the area where an antenna can read a tag. Both factors are related to the distance a tag can be read from an antenna. Determining the gain and beam width necessary for an application can be the difference between success and failure in an installation. For instance, if you are trying to track a person as they pass by a door, but don’t want to read them through the wall, you would want a wide beam width and medium gain. For a vehicle application, a high gain and narrow beam width are more likely desired.

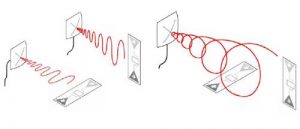

Polarization: Next to consider is the antenna polarization. UHF RFID passive antennas can be circularly or linearly polarized. Linearly polarized antennas send radio frequency (RF) waves in a single plane, allowing them to read tags that are correctly oriented at greater distances. Circularly polarized antennas are less affected by the tag’s orientation but have a shorter maximum range.

If you can’t consistently predict the orientation or height of the tag, then a circular antenna will more reliably read your tag, albeit with a shorter range. In the case of the tag on the helmet, we know both the approximate height and orientation of the tag, so a linear antenna gave us the best performance. But given the short distance requirements, both types gave more than satisfactory read range.

(source www.ti.com)

Number and Placement: Finally, we need to decide how many antennas are necessary for the job and how to place them at each entry/exit location. As a rough estimate, a circularly polarized antenna covers an 8-foot by 8-foot area at a range of 8 feet from the reader. Figuring out the number of antennas needed then depends on the math of your area to cover. More overlap will provide better likelihood of not missing a tag as it passes by. Additionally, the entry and exit antennas needed to be far enough away so that they don’t conflict with each other, but close enough so that no area in the passageway fell out of range. For our scenario, there are 2 drive-through portals and 2 walk-through portals. We used 4 antennas, 2 on each side of the driveway for the 10-12 foot wide drive-through portals. For the smaller 4-5 foot wide walk-through portals, we only needed 2 total antennas, with 1 antenna on each side.

That about wraps it all up! We are very excited about this project and can’t wait to see how much it will improve the everyday lives of the employees who will be using it!